Premium Core Technology allows for tighter tolerances and cleaner castings. With this process, non-machined areas of the rotors are more detailed.

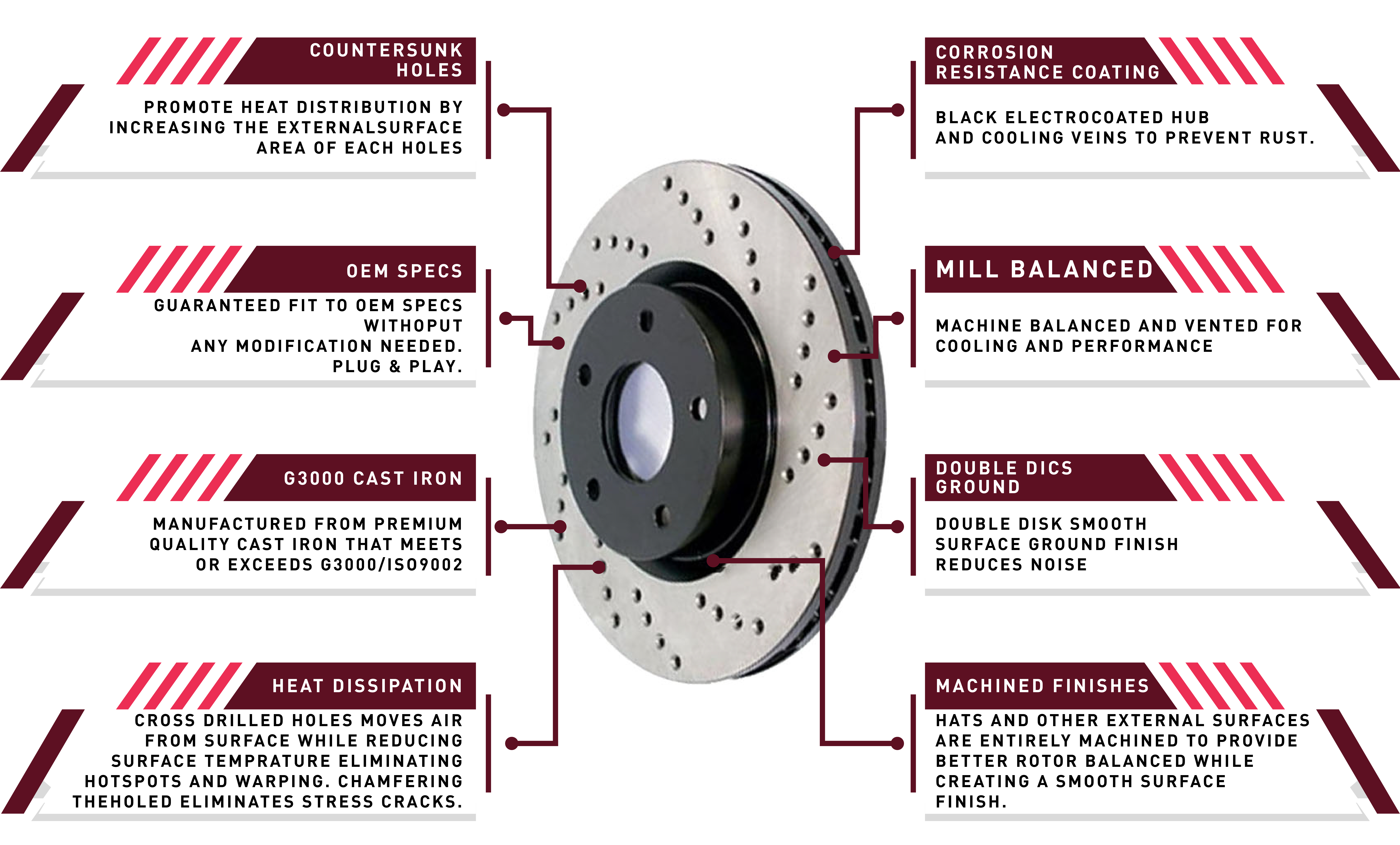

Machine Balanced for smooth braking.

Multiple Vane configurations for heat dissipation.

Non-Directional Swirl Finish promotes brake pad bedding and eliminates the need for machining prior to installation.

DuraGo® (formerly Dura International) has engineered a new line of Electrophoretic Coated Brake Rotors that offer dynamic performance with the utmost in corrosion resistance. Our new Premium Brake Rotors have superior esthetics and pricing values that will strike a chord with the professional installer and automotive enthusiast.

Electrophoretic Coating utilizes a form of electroplating to apply a rust resistant coating directly to the rotor resulting in a highly corrosion-resistant finish.

Premium Core Technology allows for tighter tolerances and cleaner castings. With this process, non-machined areas of the rotors are more detailed.

Machine Balanced for smooth braking.

Multiple Vane configurations for heat dissipation.

Non-Directional Swirl Finish promotes brake pad bedding and eliminates the need for machining prior to installation.

DBC has engineered a new line of Electrophoretic Coated Brake Rotors that offer dynamic performance with the utmost in corrosion resistance. Our new Premium Brake Rotors have superior esthetics and pricing values that will strike a chord with the professional installer and automotive enthusiast.

Electrophoretic Coating utilizes a form of electroplating to apply a rust resistant coating directly to the rotor resulting in a highly corrosion-resistant finish.

Premium Core Technology allows for tighter tolerances and cleaner castings. With this process, non-machined areas of the rotors are more detailed.

Machine Balanced for smooth braking.

Multiple Vane configurations for heat dissipation.

Non-Directional Swirl Finish promotes brake pad bedding and eliminates the need for machining prior to installation.

(where applicable)

For replacement brake pads that are designed for your vehicle, trust the name that manufacturers trust—DBC Ultra Premium Ceramic Pad .Manufactured from carefully selected materials designed to help minimize and/or virtually eliminate unwanted brake dust, DBC Ultra Premium Ceramic Pad provide consistent, smooth stopping power across a wide range of driving conditions, including panic stops.

Engineered to eliminate noise, vibration, and harshness.

Vehicle-optimized ceramic formulas for superior performance.

Ultra-low dusting for cleaner wheels and tires.

Environmentally friendly and adhere to the low copper requirements under California and Washington restrictions.

Non-Directional Swirl Finish promotes brake pad bedding and eliminates the need for machining prior to installation.

High-Carbon metallurgy is used to provide optimal thermal conductivity that helps Prevent Brake Judder.

The high carbon content also has better sound dampening characteristics to ensure quiet braking and higher resistance to distortion and thermal cracking while improving your braking safety and performance