Carbon-Fiber Ceramic formula offers extreme braking performance that is designed for muscle cars and performance vehicles.

Dust-free braking performance.

Premium stainless steel shims provide better heat dissipation & virtually noise-free braking.

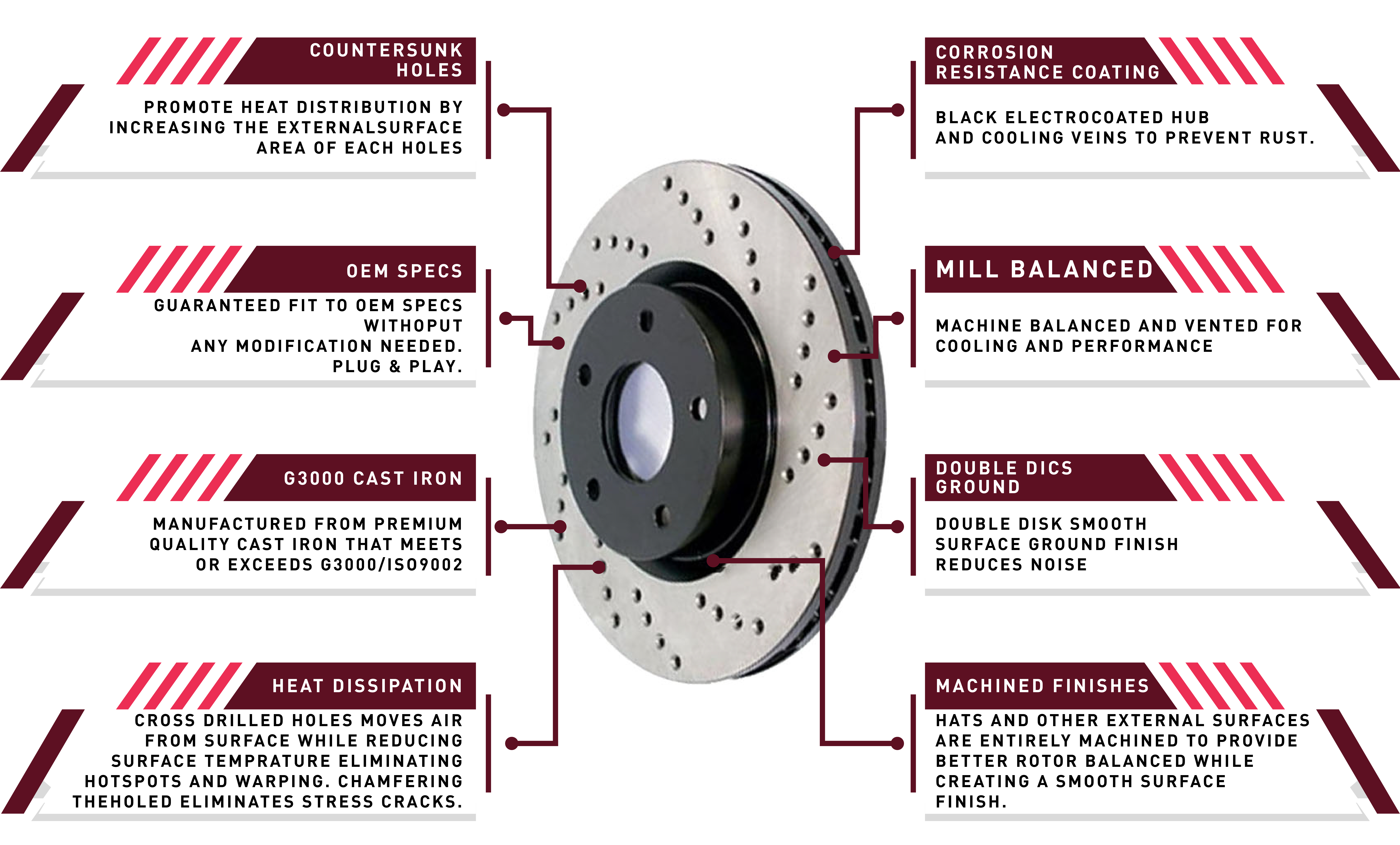

Rotors (except for hub assemblies) are electro plated for maximum protection against rust.

Drilled ONLY performance rotors for maximum cooling and longevity.

Includes ceramic brake lubricant and premium stainless steel hardware kit.

High-Carbon metallurgy is used to provide optimal thermal conductivity that helps Prevent Brake Judder.

The high carbon content also has better sound dampening characteristics to ensure quiet braking and higher resistance to distortion and thermal cracking while improving your braking safety and performance

ProCarbon Certified Brake Pads

(Where Applicable)

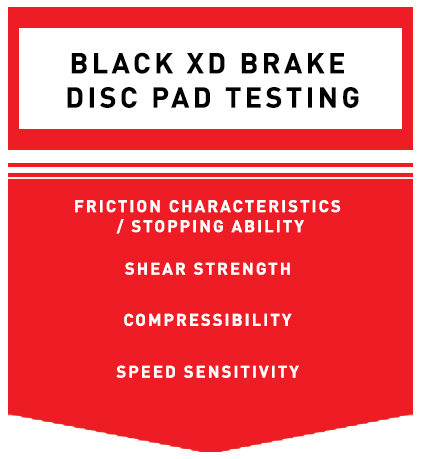

The regulation specifies brake pads and linings are measured for cold performance, speed sensitivity, friction behavior, compressibility, shear, and hardness.

Brake Sensors

OES (Original Equipment Supplier) to BMW and Mercedes included where applicable

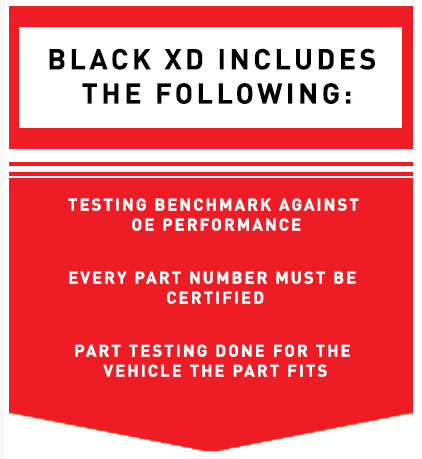

Black XD guarantees the same performance as the OE brake component.

In North America, there is no government regulation that requires brake parts to be certified to meet OE specifications prior to being sold.

However, Europe has strict quality standards.

Black XD is the European regulatory standard for the braking industry.

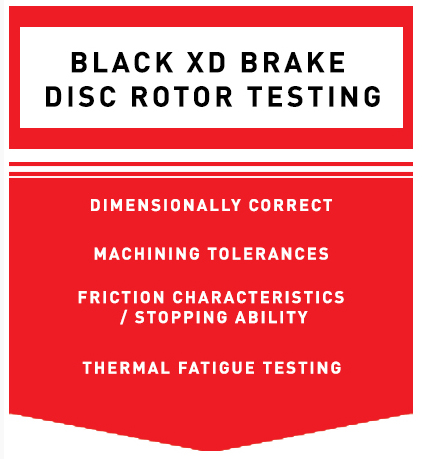

The European regulation requires testing to ensure that braking components match OEM fitment and function.